Locate the Perfect Pipe Materials for every single Application in Your Industry

Choosing the ideal pipeline products is a vital job for any kind of industry. Different products offer distinct objectives, and the selection can significantly affect performance and safety and security. It requires careful consideration of elements like dimension, application demands, and conformity with regulations. Understanding these aspects will assist experts in making informed decisions. As they navigate these complexities, the concern stays: exactly how can one assure they are choosing the very best choices offered?

Comprehending Various Pipeline Materials

When choosing pipe materials for numerous applications, recognizing the distinctions amongst pipe materials is vital. Each kind of pipeline product offers distinct residential or commercial properties and benefits suited for specific usages. PVC pipes are lightweight, corrosion-resistant, and affordable, making them optimal for domestic plumbing and watering systems. On the various other hand, CPVC pipes can stand up to greater temperatures, making them suitable for warm water applications.

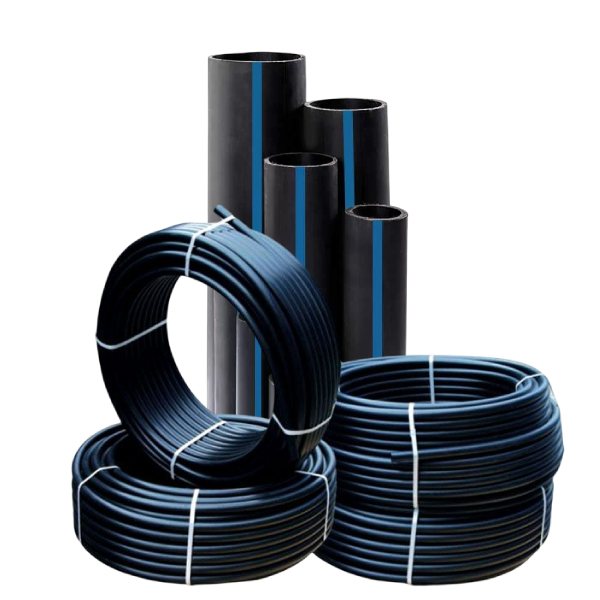

Metal pipes, such as copper and galvanized steel, are recognized for their durability and stamina, typically used in commercial settings. Copper is also immune to rust and has anti-bacterial homes. In contrast, steel pipelines are favored for their robustness in high-pressure systems. In addition, polyethylene pipes are adaptable and resistant to chemicals, typically made use of in gas and water distribution. Ultimately, the option of pipe product significantly impacts the efficiency, durability, and safety and security of the desired application, demanding mindful consideration by sector professionals.

Analyzing Size and Requirements

Selecting the proper dimension and specifications for pipe products is necessary for guaranteeing suitable performance in any type of application. The diameter, size, and wall surface density of pipelines straight affect their capacity to manage liquid circulation and pressure. It is important to match these dimensions to the needs of the system in which they will be utilized. Requirement dimensions are often offered, yet custom specs may be needed for specialized applications.

In addition, the specs should consist of factors to consider such as material compatibility, temperature level tolerance, and pressure scores. These aspects aid prevent failures and guarantee durability. Appropriately reviewing dimension and specifications not only enhances functional efficiency but additionally minimizes costs related to product waste and system downtime.

Ultimately, an extensive understanding of the required dimension and requirements enables markets to make informed options, bring about successful setups and reliable performance in their respective applications.

Assessing Application Demands

How can one guarantee that pipeline products fulfill the certain demands of an application? The very first step includes a complete understanding of the operational environment (American Plastics LLC Midland). Elements such as temperature level variations, stress degrees, and exposure to harsh materials should be thoroughly considered. Next off, the intended use the pipelines plays an essential function; whether they are meant for transporting fluids, gases, or see it here solids can considerably affect material option

Furthermore, the compatibility of pipeline materials with the liquids being transported is vital to ensure long life and performance. It is additionally recommended to consult market requirements and regulations that may determine particular needs for materials and construction techniques. Looking for input from experienced experts in the area can supply valuable insights. By carefully evaluating these application demands, one can with confidence pick pipe materials that not just fit but stand out in their intended duties, enhancing effectiveness and integrity in operations.

Thinking About Price and Schedule

Price and schedule are vital variables that affect the selection of pipe materials for any type of application. Services have to evaluate their monetary restraints while assuring they have accessibility to the necessary materials (American Plastics LLC). Higher-quality pipes may feature raised prices, yet they often offer improved resilience and durability, which can justify the financial investment gradually

In addition, the schedule of certain pipeline materials can vary significantly based on place and vendor connections. Companies need to create a trusted network of distributors to ensure that they can source products without delay and stay clear of task delays.

Additionally, variations in market need and global supply chain concerns can affect both cost and accessibility. Because of this, it is crucial for industries to remain educated about market fads and preserve flexibility in their supply chain strategies. Inevitably, a well-considered method to set you back and accessibility will boost operational efficiency and task success.

Making Sure Compliance and Safety And Security Criteria

To browse these complexities, business should carry out comprehensive study on appropriate criteria such as ISO, ASTM, and ASME. Working together with distributors who focus on compliance can streamline the choice procedure, making sure that all pipeline supplies fulfill requisite certifications. Routine audits and examinations better enhance security by recognizing prospective dangers or shortages in materials. By prioritizing conformity and safety and security, organizations not only secure their labor force but also improve their functional performance and credibility within the market. Selecting the best pipe materials is an essential action in the direction of achieving a risk-free and certified functioning setting.

Secure Regularly Asked Inquiries

What Are the very best Brands for Pipeline Supplies in My Industry?

Leading brands for pipe materials consist of PVC, Victaulic, additional reading and Mueller. Their online reputation for durability, development, and comprehensive product ranges makes them preferred options across various industries, guaranteeing reputable performance and high quality in pipeline applications.

Just how Do I Keep Pipelines to Make Certain Long Life?

To preserve pipes for durability, regular inspections, cleansing, and appropriate sealing are vital. Furthermore, avoiding severe temperature levels and making use of protective finishings can avoid corrosion, eventually prolonging the lifespan and efficiency of the piping system.

What Devices Are Necessary for Pipe Installation?

Essential devices for pipe installation include monkey wrench, cutters, installations, a level, measuring tape, and a welding torch. These tools help with exact dimensions, protected links, and total performance, making sure a successful pipeline installation procedure.

Can I Tailor Pipe Products for Certain Projects?

Where Can I Discover Specialist Recommendations on Pipeline Choice?

Specialist guidance on pipe choice can commonly be found via industry-specific discussion forums, manufacturer agents, and professional trade organizations. Additionally, specialized web sites and neighborhood providers regularly offer examinations to aid guide finest selections for particular jobs.

When choosing pipeline supplies for different applications, comprehending the differences among pipeline products is necessary. Selecting the suitable dimension and requirements for pipe supplies is necessary for assuring perfect performance in any type of application. Just how can one assure that pipe supplies satisfy the certain needs of an application? Ensuring compliance with policies and security requirements is vital in the option of pipeline products for various applications. Important tools for pipe installation include pipe wrenches, cutters, fittings, a level, measuring tape, and a soldering iron.